About Us

About Protech Model

Over 35 Years Of Experience

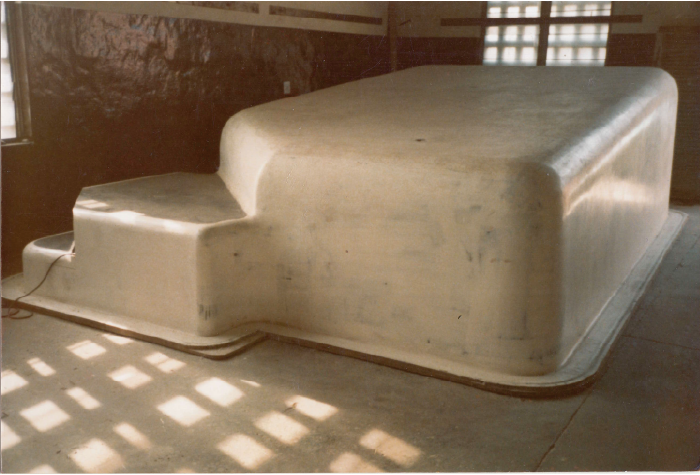

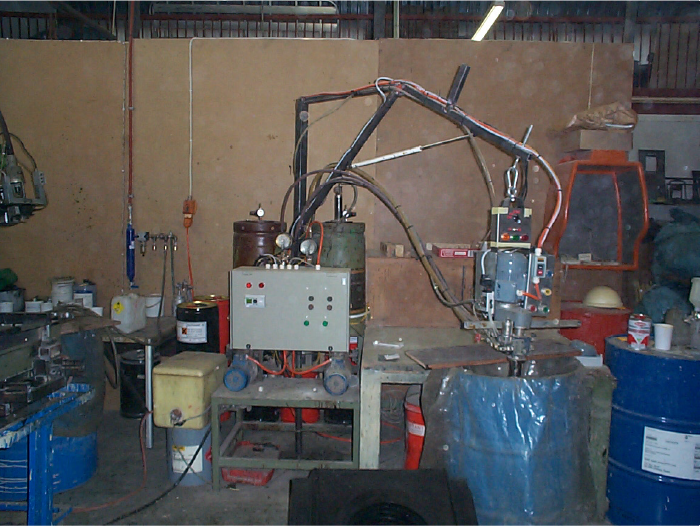

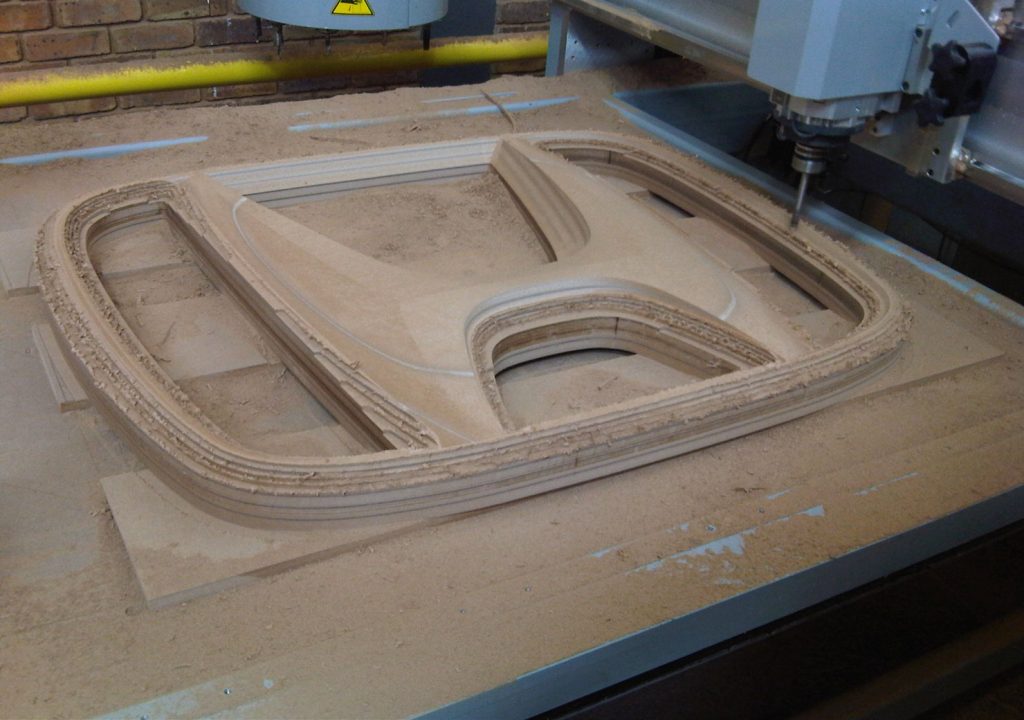

Protech Model is recognized as one of South Africa’s leading vacuum forming specialists, proudly serving both the 3D signage and industrial sectors across the country and into Africa. By working closely with leading signage solution companies, we have built a reputation for delivering consistent quality, reliable service, and innovative solutions. Our fully integrated turnkey facility allows us to manage every stage of the process — from design and tooling to production and finishing. This “start-to-finish” capability ensures complete quality control and accountability, giving our clients confidence in the final product.